Delta AH Series Expansion Modules – Programmable Controller AH Series

PRODUKTPARAMETER

- Comprehensive digital and analog I/O module options

- Temperature measurement modules for accurate monitoring

- Network and remote I/O communication modules

- Motion control modules to support advanced automation

Beschreibung

PRODUKTMERKMALE

Provides digital modules including input, output, and mixed types.

Offers analog modules for both input, output, and mixed configurations.

Supports temperature measurement modules for precise monitoring.

Includes network modules, remote I/O communication modules, and motion control modules to extend automation capabilities.

ANWENDUNGSBEREICHE

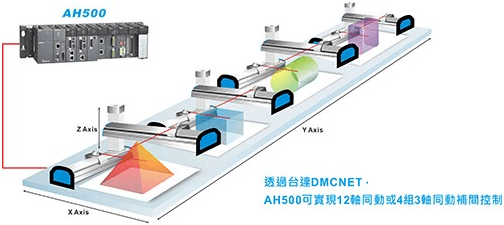

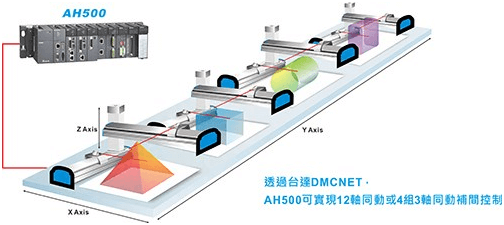

Industrial machinery uses the excellent motion control function of AH500 to realize any three-axis linear interpolation, any two-axis arc interpolation, and any three-axis spiral interpolation and continuous interpolation functions. Through Delta’s DMCNET high-speed communication network architecture, it can achieve 12-axis simultaneous motion or 4 groups of 3-axis simultaneous motion tweening functions within a 1ms command cycle. Whether it is complex process control or precise motion control requirements, it can be realized through AH500, which is effectively used in various industrial machines, such as building materials machines, warp knitting machines, food packaging machines, etc.

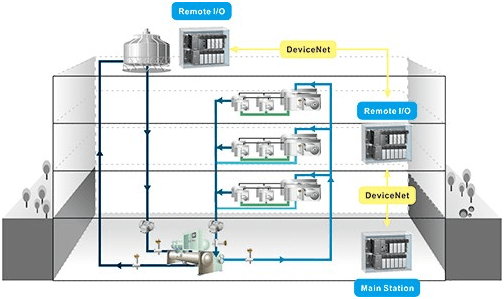

AH500 is a modular controller designed for various high-end automation system applications. Its diverse module selection and excellent system architecture scalability provide excellent solutions for various system application industries; such as remote controllers for building air conditioning (HVAC) and papermaking industry. For I/O needs, the AH500 master station can be used as a central control system to disperse the remote I/O of the AH500 at different floor locations in the HVAC system or at different process stages in the papermaking industry, providing a complete solution for building automation or factory automation.

The system applies the excellent motion control function of AH500 to realize any three-axis linear interpolation, any two-axis arc interpolation, and any three-axis spiral interpolation and continuous interpolation functions. Through Delta’s DMCNET high-speed communication network architecture, it can achieve 12-axis simultaneous motion or 4 groups of 3-axis simultaneous motion tweening functions within a 1ms command cycle. Whether it is complex process control or precise motion control requirements, it can be realized through AH500, which is effectively used in various industrial machines, such as building materials machines, warp knitting machines, food packaging machines, etc.

AH500 is a modular controller designed for various high-end automation system applications. Its diverse module selection and excellent system architecture scalability provide excellent solutions for various system application industries; such as remote controllers for building air conditioning (HVAC) and papermaking industry. For I/O needs, the AH500 master station can be used as a central control system to disperse the remote I/O of the AH500 at different floor locations in the HVAC system or at different process stages in the papermaking industry, providing a complete solution for building automation or factory automation.

TECHNISCHE DATEN

FAQs

Als integriertes Handels- und Produktionsunternehmen bieten wir eine vollständige Palette von Delta-Stromversorgungen an, darunter Schaltnetzteile, industrielle Stromversorgungsmodule und geregelte Gleichstromversorgungen, die für die industrielle Automatisierung und verschiedene elektronische Geräte geeignet sind.

Ja. Wir bieten maßgeschneiderte Lösungen auf der Grundlage der Kundenanforderungen, einschließlich Spannung, Leistung und Funktionserweiterungen, mit professioneller technischer Unterstützung, um die Machbarkeit zu gewährleisten.

Der Versand erfolgt über zuverlässige Logistik- und Kurierdienste, die eine lückenlose Nachverfolgung anbieten, um sicherzustellen, dass die Produkte sicher und pünktlich beim Kunden ankommen.

Das Verfahren ist einfach: Modell auswählen → Anforderungen einreichen → Lösung bestätigen → Zahlung vereinbaren → Lieferung und technische Beratung. Wir bieten umfassende Unterstützung, damit jeder Schritt reibungslos abläuft.

Wir bieten Original-Herstellergarantie, Ersatzteilversorgung, Betriebsanleitung, Wartung und Fehlerbehebung, um einen stabilen und zuverlässigen Betrieb der Delta-Netzteile zu gewährleisten.