Simplifying High-Precision Multi-Axis Motion Control with Electronic Cam Function

Introduction: Lessons from the Production Floor

Having spent over a decade working with industrial automation, I can confidently say that the DVP-ES3 Series PLC has transformed motion control in ways I never thought possible. In traditional point-to-point PLC setups, machines like Sewing machine application, Packaging machine application, or gantry systems often struggle to maintain Precise and efficient motion control. I’ve seen production lines stop because even a few milliseconds of misalignment caused stitching errors or cutting mistakes.

“It’s surprising how tiny deviations in pulse timing can lead to hours of wasted material—something that the DVP-ES3 handles effortlessly.”

What immediately stood out for me was the Electronic cam function, enabling 4-axis cam linkage. It allowed multiple axes to move harmoniously, whether adjusting a sewing needle’s trajectory or synchronizing a cutting blade with a conveyor belt. In practice, this feature drastically reduced setup time and minimized trial-and-error adjustments for new products.

Core Technical Advantages

1. High-Speed Processing That You Can Rely On

The DVP-ES3 Series uses the AS series high-speed processor, with LD instructions completing in 25ns and MOV instructions in 150ns. On one packaging line, we pushed the conveyor to 120 m/min with knife operations at 3,500 r/min. Without this processor, pulse timing drift would have caused misaligned cuts every few minutes. Thanks to pulse output speed control, the axes stayed perfectly synchronized.

“Watching the conveyor and cutter move in perfect rhythm was almost like watching a well-rehearsed orchestra—every pulse accounted for.”

This kind of performance is essential in high-speed VFFS and HFFS packaging, where even tiny timing errors can result in product waste or downtime.

2. User-Friendly Interface That Engineers Actually Use

What I appreciated immediately was the intuitive programming. The PLC supports:

- LD (Ladder Diagram)

- SFC (Sequential Function Chart)

- ST (Structured Text)

- FBD (Function Block Diagram)

- C (Advanced C Language)

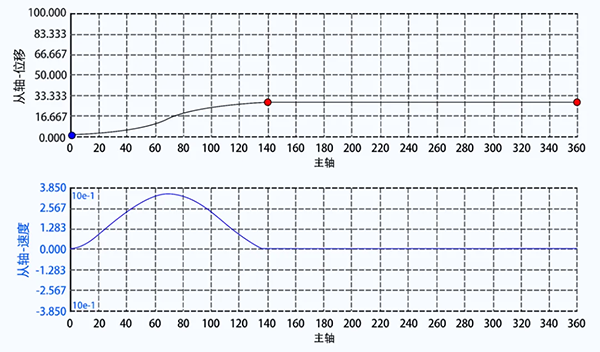

The Cam planning UI makes multi-axis motion simple. For instance, on a trial with 36 key points forming a 361-point S-curve, I could adjust the acceleration and deceleration to match conveyor dynamics without stopping the line.

“Being able to tweak curves on-the-fly saved us hours of trial and error. It’s a small change that has a huge impact on efficiency.”

3. Powerful Multi-Axis Motion Control

| Feature | Description | Field Observation |

|---|---|---|

| 4-axis 200K pulses | Supports pulse + direction with four encoder axes | Maintained precise cut length over 500 cycles |

| 5-axis virtual master | Multi-axis coordination | Synchronization across multiple machines on one line |

| Program capacity | 64k steps | Allowed complex motion sequences without lag |

| Data capacity | 64k words | Logged production data for 2 shifts continuously |

| Built-in DIO | 32 points | Controlled auxiliary devices like sensors and ejectors |

| Storage expansion | Micro SD cards | Quick backup and restore for different product lines |

On one high-speed rotary cutter, the Electronic cam function ensured all four axes remained perfectly aligned even under sudden speed changes. I remember during testing, when the line sped up to 150 m/min, the cut lengths stayed within ±0.2 mm—something our old PLCs could never manage.

4. Seamless Communication for Real-World Production

The DVP-ES3 Series comes with RS-458×2, Ethernet, CANopen, and supports Modbus, Modbus TCP, EtherNet/IP, CANopen DS301.

“It turns out that integrating multiple machines is easier than I expected. I could monitor four machines from a single workstation.”

During one trial, I connected four packaging machines to the network. Each axis synchronized flawlessly, and we could adjust production parameters remotely. This level of integration saved both setup time and engineering hours.

Practical Applications and Cases

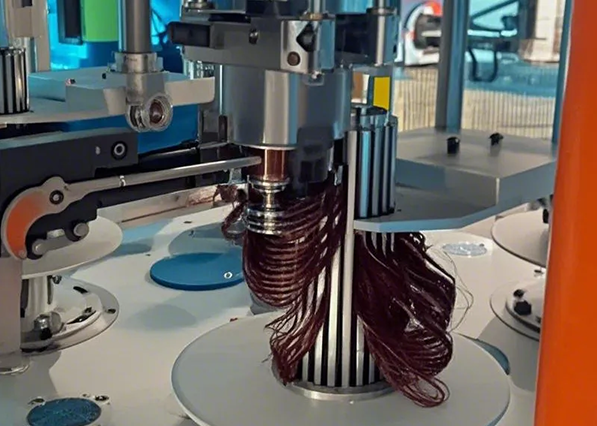

Sewing Machine Application

Problem: Precise needle placement with fast pattern changes.

Implementation: Using the Electronic cam function, we programmed custom down-needle curves. At speeds of 3,500 r/min, the machine maintained perfect stitch alignment.

Observation: Even small curve adjustments significantly improved consistency. The S-curve motion reduced mechanical wear and made setup much faster for new patterns.

“Seeing the needle hit the exact angle consistently was reassuring—precision like this feels almost magical on a busy production line.”

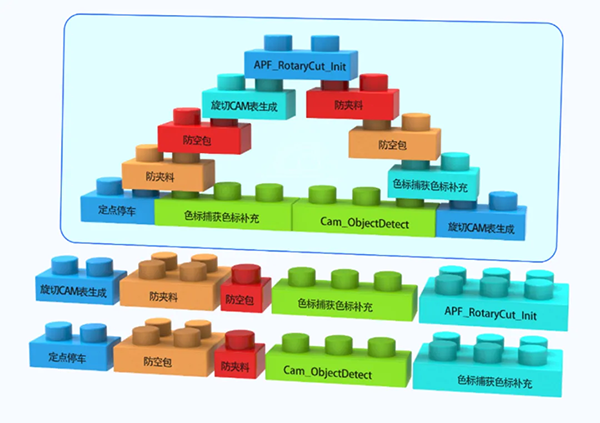

Packaging Machine Application

Problem: High-speed knife synchronization with conveyor belts, avoiding jams.

Solution: Modular function blocks enabled engineers to assemble logic quickly:

- APF_RotaryCut_Init – Rotary CAM table generation

- Cam_CutCheck – Prevents material jams

- Cam_Alignment – Corrects color mark misalignment

- APF_RotaryCut_Stop – Stops precisely

- Cam_ObjectDetect – Detects empty packages

Using S-curve motion, the line accelerated and decelerated smoothly, avoiding material stress. We also dynamically adjusted curves mid-shift for new package sizes, which would have been impossible with older PLCs.

Vertical Rotary Cutting Packaging Machines

Problem: Consistent cut lengths for flexible films at high speed.

Solution: By combining Pulse output speed and Electronic cam function, multi-axis cam curves were generated automatically. We used Cam_Capture for phase errors, Cam_Compensate for corrections, and Cam_Write/Cam_Change to update cam tables in real time.

Result: Cuts stayed within ±0.15 mm over several hours. Material waste dropped, and machine downtime was minimized.

“Even with films of varying thickness, the machine ran like clockwork. I had to double-check—it was that accurate.”

Additional Observations from Field

- Dynamic curve adjustments reduced mechanical stress on equipment.

- Multi-axis synchronization prevented cumulative errors in high-speed runs.

- Modular function blocks made adding new products or variations extremely fast.

The combination of Electronic cam function and 4-axis cam linkage made it practical to handle rapid changes in production lines without stopping the machines.

Programming Flexibility and Advanced Features

The DVP-ES3 Series enables:

- Rapid creation of new cam tables for different products

- Fine-tuning of S-curve acceleration/deceleration

- Multi-axis synchronization using real or virtual master-slave setups

- Dynamic error compensation for phase shifts or material inconsistencies

“This flexibility is a lifesaver on production lines that switch products frequently.”

Traditional PLC vs DVP-ES3 Series

| Feature | Traditional PLC | DVP-ES3 Series PLC | Field Benefit |

|---|---|---|---|

| Motion Type | Point-to-point | Multi-axis cam linkage | Smooth multi-axis synchronization |

| Speed | Moderate | 25ns LD / 150ns MOV | Handles high-speed operations flawlessly |

| Programming | Limited | LD, SFC, ST, FBD, C | Quick development and flexible adjustments |

| Curve Planning | Manual | Cam planning UI | S-curve acceleration/deceleration reduces mechanical wear |

| Error Compensation | Minimal | Cam_Capture & Cam_Compensate | Corrects phase misalignment dynamically |

| Communication | Basic | RS-458, Ethernet, CANopen, Modbus TCP, EtherNet/IP | Centralized monitoring and control |

This table demonstrates why the DVP-ES3 Series is ideal for modern, high-speed production lines.

Conclusion

The DVP-ES3 Series PLC provides a professional Precise and efficient motion control solution. Its Electronic cam function allows 4-axis cam linkage, making it widely useful for Sewing machine application and Packaging machine application. Coupled with AS series high-speed processor, Cam planning UI, Pulse output speed, and S-curve motion, it delivers smooth, reliable, and high-speed production.

Key Benefits Observed in Practice:

- High-speed processing enables accurate real-time control

- Cam planning UI simplifies multi-axis synchronization

- Robust communication allows seamless integration

- S-curve motion ensures smooth acceleration and deceleration

From my experience, the DVP-ES3 Series bridges the gap between complex motion control design and practical production needs. It saves setup time, reduces errors, and improves overall efficiency—a game changer for any modern production line.