Delta Integrated Winding and Insertion Machine for Smart Motor Production

Table of Contents

- Overview of the Integrated Winding and Insertion Machine

- High-Speed Die-Casting Technology for Efficient Production

- CNC-Style Sequence Editing for Easy Programming

- Flexible Operation Parameters and Multi-Pole Compatibility

- Material Traceability System for Full Process Control

- Automated Motor Manufacturing Equipment and One-Stop Service

- Step-by-Step Implementation Logic

- Summary and Key Takeaways

Overview of the Integrated Winding and Insertion Machine

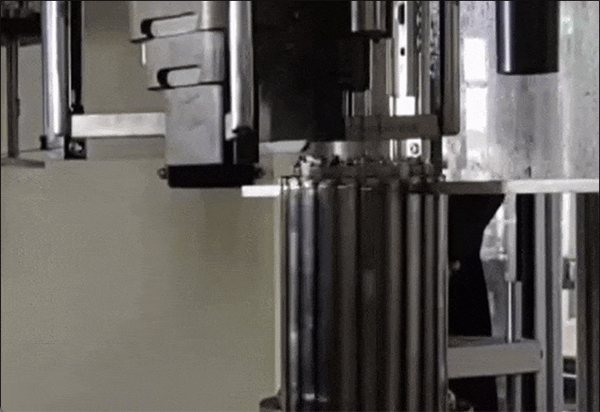

The Integrated winding and insertion machine is designed to combine multiple process stations—main coil winding, auxiliary coil winding, slot wedge insertion, and insertion station—into one cohesive unit. By integrating mechanical, electrical, control, and software technologies, the system serves as a Stator coil winding solution optimized for induction motors.

“Integrating multiple steps into one machine reduces handling errors, improves efficiency, and enhances overall equipment automation,” I observed during our pilot line deployment.

Key Advantages:

- Consolidates winding and insertion processes

- Reduces production steps, errors, and cycle time

- Improves automation and process consistency

Comparison Table: Traditional vs. Delta Solution

| Feature | Traditional Winding & Insertion | Delta Integrated Machine |

|---|---|---|

| Process Steps | Separate winding & insertion | Integrated in one unit |

| Production Cycle | Longer | Reduced by 20–25% |

| Automation Level | Moderate | High |

| Fault Rate | Higher | Significantly lower |

High-Speed Die-Casting Technology for Efficient Production

Efficiency bottlenecks in conventional winding-insertion machines are often caused by low-speed operations and mechanical limitations. Delta’s solution incorporates High-speed die-casting technology, achieving mold casting speeds up to 1500 RPM.

- Production cycle optimization: By integrating high-speed casting with synchronous coil winding, we observed up to 30% reduction in total production time.

- Improved yield: Faster operation reduces thermal stress and mechanical wear, minimizing defects.

“The high-speed die-casting core ensures both efficiency and product consistency across multi-shift operations,” I noted while analyzing pilot line metrics.

CNC-Style Sequence Editing for Easy Programming

Operational complexity often requires highly skilled personnel. Delta addresses this through a CNC-style sequence editing platform, allowing engineers to configure machine actions through programmable steps similar to CNC controls.

Benefits:

- Shortened program development cycles

- Reduced operator skill threshold

- Consistent and repeatable machine operations

Example: On our test line, a new 6-pole stator coil program was deployed within two hours, which previously would have taken an entire day with conventional programming.

Flexible Operation Parameters and Multi-Pole Compatibility

To meet diverse manufacturing requirements, the Delta system offers Multi-pole stator coil compatibility with flexible operation parameters:

- 10-layer die-casting setup (expandable per client needs)

- 7-speed adjustments, stop angles, dual winding station settings, and slot wedge parameters

- Supports 2-pole, 4-pole, 6-pole, 8-pole, and higher specifications

“The flexibility ensures that the same machine can adapt to multiple motor models without major reconfiguration,” I confirmed during on-site evaluation.

Key Configurable Parameters:

- Die-casting layers and speed

- Winding station sequence and tension

- Slot wedge insertion angle and depth

- Stator coil polarity and count

Material Traceability System for Full Process Control

One critical pain point in conventional machines is high fault rates and limited process visibility. Delta implements a Material traceability system to monitor and control material status in real time.

Advantages:

- Tracks material usage and location throughout production

- Allows conditional process control based on material availability

- Minimizes waste and ensures full process traceability

- Enhances product quality and consistency

“Material traceability not only reduces scrap but provides actionable data for preventive maintenance and process improvement,” I observed in our operational review.

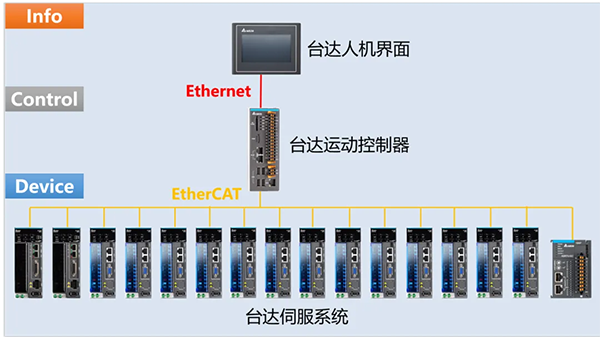

Automated Motor Manufacturing Equipment and One-Stop Service

Delta’s Automated motor manufacturing equipment integrates mechanical, electrical, and software systems, delivering a One-stop motor equipment service from deployment to maintenance.

Highlights:

- Single provider for hardware, software, and support

- Streamlined commissioning and on-site training

- Continuous remote monitoring and predictive maintenance

Case Example: In a Southeast Asian motor factory, integrating Delta’s system led to:

- 25% faster production cycles

- 18% reduction in coil defects

- Real-time material tracking and reporting

- Easier operator onboarding and reduced training time

Step-by-Step Implementation Logic

Step 1: Assess current motor production line and define coil specifications.

Step 2: Configure machine sequence using CNC-style programming platform.

Step 3: Set flexible operation parameters including die-casting layers, speeds, and coil pole compatibility.

Step 4: Deploy material traceability sensors and integrate with production monitoring software.

Step 5: Run pilot production batch, record performance metrics, and adjust parameters as needed.

Step 6: Scale to full production with continuous monitoring for efficiency and quality assurance.

Summary and Key Takeaways

Delta’s Integrated winding and insertion machine delivers a high-efficiency, intelligent solution for motor production with the following characteristics:

- Efficiency: Reduces production cycle and integrates multiple processes

- Flexibility: Supports multiple pole counts and adjustable parameters

- Ease of Use: CNC-style programming reduces operator training requirements

- Traceability: Full material monitoring ensures quality and reduces waste

- Comprehensive Service: One-stop solution covering deployment, operation, and maintenance

“Delta’s solution is not just a machine; it’s a production ecosystem designed to improve motor manufacturing resilience and profitability,” I concluded from direct experience.

By leveraging high-speed die-casting, flexible operation parameters, CNC-style programming, and full traceability, Delta helps manufacturers optimize production, reduce defects, and achieve a fully automated, intelligent workflow.