Delta AH Series Standard CPU – Programmable Controller AH Series

PRODUCT PARAMETERS

- Fully integrated high-level hardware and software automation system

- ISPSoft with five programming languages and graphical interface

- Backplane extension up to 100 meters for flexible planning

- Supports hot-swappable modules for convenient maintenance

Description

PRODUCT FEATURES

High-level hardware and software fully integrated automation system.

ISPSoft programming software provides five programming languages with a graphical interface for easy development.

Proximity extension cables between backplanes can reach up to 100 meters, offering flexible hardware planning.

Supports hot-swappable modules, enhancing maintenance convenience and reducing downtime.

APPLICATION FIELDS

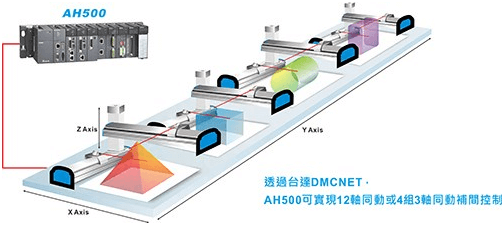

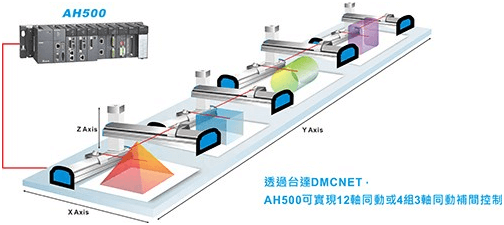

Industrial Machinery Application The excellent motion control function of the AH500 can realize any three-axis linear interpolation, any two-axis arc interpolation, and any three-axis spiral interpolation and continuous interpolation functions. Through Delta’s DMCNET high-speed communication network architecture, it can achieve 12-axis simultaneous motion or 4 groups of 3-axis simultaneous motion tweening functions within a 1ms command cycle. Whether it is complex process control or precise motion control requirements, it can be realized through AH500, which is effectively used in various industrial machines, such as building materials machines, warp knitting machines, food packaging machines, etc.

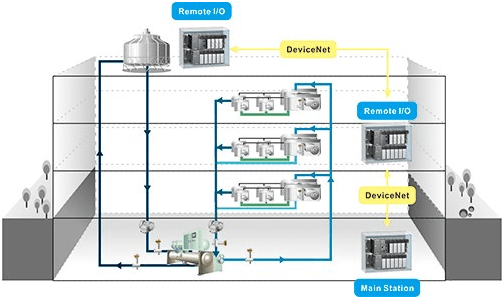

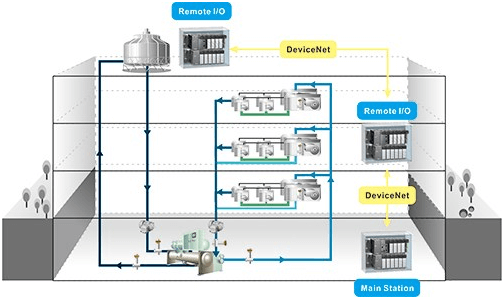

AH500 is a modular controller designed for various high-end automation system applications. Its diverse module selection and excellent system architecture scalability provide excellent solutions for various system application industries; such as remote controllers for building air conditioning (HVAC) and papermaking industry. For I/O needs, the AH500 master station can be used as a central control system to disperse the remote I/O of the AH500 at different floor locations in the HVAC system or at different process stages in the papermaking industry, providing a complete solution for building automation or factory automation.

System Application The excellent motion control function of AH500 can realize any three-axis linear interpolation, any two-axis arc interpolation, and any three-axis spiral interpolation and continuous interpolation functions. Through Delta’s DMCNET high-speed communication network architecture, it can achieve 12-axis simultaneous motion or 4 groups of 3-axis simultaneous motion tweening functions within a 1ms command cycle. Whether it is complex process control or precise motion control requirements, it can be realized through AH500, which is effectively used in various industrial machines, such as building materials machines, warp knitting machines, food packaging machines, etc.

AH500 is a modular controller designed for various high-end automation system applications. Its diverse module selection and excellent system architecture scalability provide excellent solutions for various system application industries; such as remote controllers for building air conditioning (HVAC) and papermaking industry. For I/O needs, the AH500 master station can be used as a central control system to disperse the remote I/O of the AH500 at different floor locations in the HVAC system or at different process stages in the papermaking industry, providing a complete solution for building automation or factory automation.

TECHNICAL SPECIFICATIONS

32-bit SoC Motion Controller Specifications

| Category | Specifications |

|---|---|

| Processor | 32-bit SoC |

| I/O Expansion Points | DIO: 4,352 points AIO: 544 channels RIO: over 100,000 points |

| Program Capacity | 384k steps (1.5 MB) |

| Data Buffer | (D+L) 256k words |

| High-Speed Program Handling | LD instruction execution: 0.02 µs |

| CPU Module Interfaces | Built-in fully isolated RS-232 / RS-422 / RS-485, Mini USB, Ethernet, SDHC card slot |

| Module Options | Digital I/O, Analog I/O, Temperature, Network, Pulse, DMCNET and EtherCAT motion control modules |

FAQs

As a trade-and-manufacturing integrated company, we offer a full range of Delta power supplies, including switching power supplies, industrial power modules, and DC regulated power supplies, suitable for industrial automation and various electronic equipment.

Yes. We provide customized solutions based on customer requirements, including voltage, power, and functional extensions, with professional technical support to ensure feasibility.

We ship via reliable logistics and courier services, offering full tracking to ensure the products reach customers safely and on time.

The process is simple: select the model → submit requirements → confirm the solution → arrange payment → delivery and technical guidance. We provide full support to ensure each step is completed smoothly.

We provide original manufacturer warranty, spare parts supply, operation guidance, maintenance, and troubleshooting services to ensure Delta power supplies operate stably and reliably.