Delta ASDA-A3 Series AC Servo System

PARAMETRI DEL PRODOTTO

- High-Speed & Precision: 3.1 kHz response with 24-bit absolute encoder.

- Advanced Motion Control: Path planning, electronic cam, and trajectory interpolation.

- Vibration Suppression: High-frequency and low-frequency filters for stable operation.

- Energy Efficiency & Compact Design: Multi-axis DC bus, regenerative energy, and reduced drive/motor size.

Descrizione

CARATTERISTICHE DEL PRODOTTO

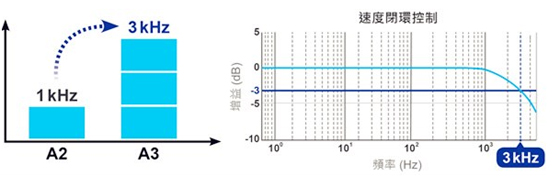

3.1 kHz Speed Response Bandwidth

The A3 response bandwidth is increased threefold, providing more real-time command following.

Significantly reduces position settling time, optimizing equipment productivity.

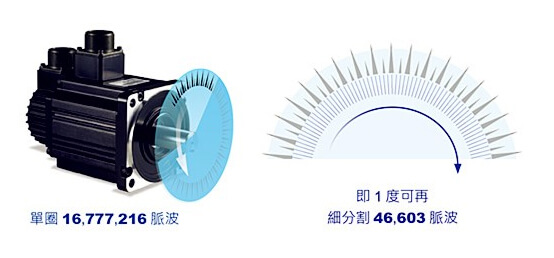

24-bit High-Resolution Absolute Encoder

Single-turn resolution of 16,777,216 pulses enables more precise positioning.

Smoother operation in low-speed machining, effectively improving surface finish quality.

Absolute encoder retains motor position even during power loss.

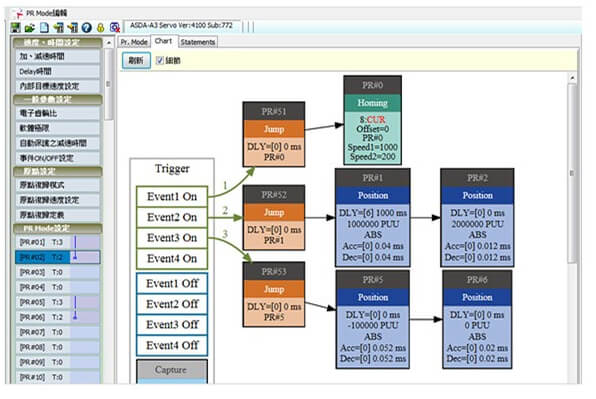

Advanced Motion Control Features

Built-in flexible motion control with added functionalities and upgrades.

Supports planning of up to 99 motion segments.

Intuitive icon-based interface for operation.

Supports arithmetic operations and comparisons.

Path merging and path jumping.

Origin return mode.

Electronic cam.

Position and speed planning.

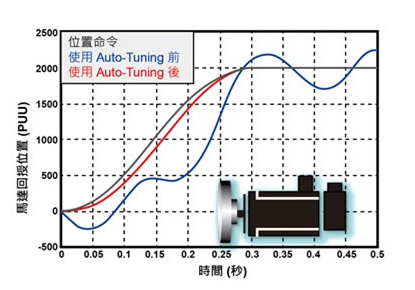

Robust Auto-Tuning Capability

Automatic gain adjustment function.

Built-in expert-level auto-tuning reduces the barrier to servo use and optimizes equipment performance.

Guided and dialog-based auto-tuning allows servo gain adjustment through simple sequential steps.

Supports both panel key and software-based automatic tuning.

Excellent Vibration Suppression

High-frequency vibration filtering.

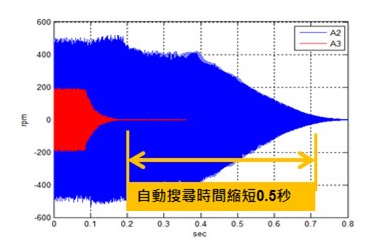

Automatic resonance frequency search time is shortened, reducing impact on the mechanism.

Suppresses five sets of high-frequency resonances simultaneously; filter bandwidth can be flexibly adjusted to reduce affected range.

Low-frequency oscillation suppression effectively reduces vibration in highly flexible machines, enhancing operational performance.

Active calculation suppression prevents end-effector shaking and increases operating speed.

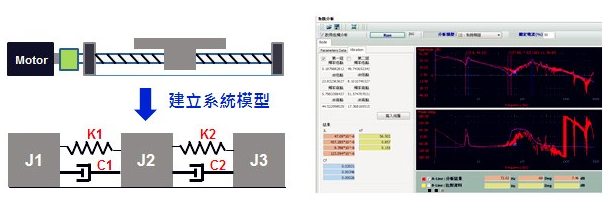

Mechanism Diagnostic Functions

Measures mechanical stiffness and damping coefficients.

Useful for verifying consistency in large-scale machine assembly.

Comparisons over different time points can assess mechanism aging and variation.

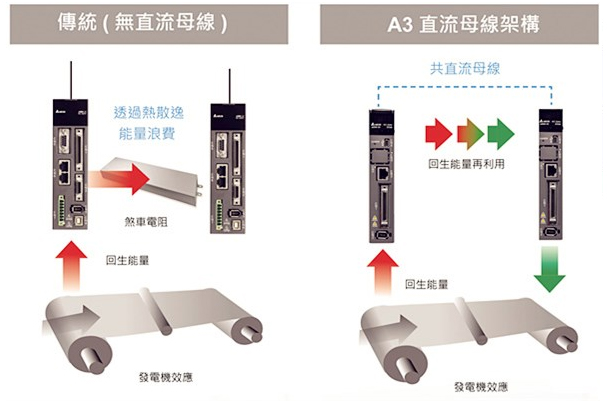

Multi-Axis Common DC Bus Design

Maintains stable DC bus voltage, enabling regenerative energy reuse and improving equipment energy efficiency.

Multiple drives using the common DC bus reduce the number of braking resistors needed, lowering costs.

Compact Physical Design

Drive width and motor length are reduced by approximately 20% (compared with A2).

Saves installation space and weight, enabling equipment miniaturization.

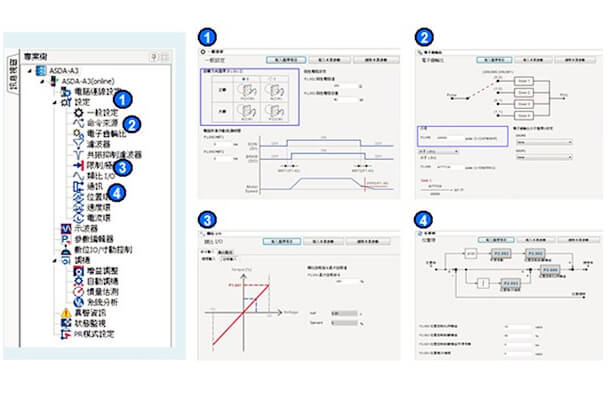

Intuitive Software Interface

New tree-structured functional menu for easy operation.

Icon-based parameter setting interface reduces errors and saves time.

APPLICATION FIELDS

| Machine Tool | Precision Engraving Machine | Gantry Machining |

|---|---|---|

| TFT Panel Cutting | IC Packaging Machine | Electronic Assembly or Inspection Equipment |

| Robotic Arm | Industrial Robot | Injection Molding Equipment |

| Labeling Equipment | Semiconductor Equipment | Textile Equipment |

Domande frequenti

In qualità di azienda integrata di commercio e produzione, offriamo una gamma completa di alimentatori Delta, tra cui alimentatori switching, moduli di alimentazione industriali e alimentatori regolati in corrente continua, adatti all'automazione industriale e a varie apparecchiature elettroniche.

Sì. Forniamo soluzioni personalizzate in base alle esigenze del cliente, comprese le estensioni di tensione, potenza e funzionalità, con un supporto tecnico professionale per garantire la fattibilità.

Spediamo tramite servizi logistici e di corriere affidabili, offrendo una tracciabilità completa per garantire che i prodotti raggiungano i clienti in modo sicuro e puntuale.

Il processo è semplice: selezionare il modello → presentare i requisiti → confermare la soluzione → organizzare il pagamento → consegna e guida tecnica. Forniamo un'assistenza completa per garantire che ogni fase sia completata senza problemi.

Forniamo la garanzia del produttore originale, la fornitura di parti di ricambio, la guida al funzionamento, la manutenzione e i servizi di risoluzione dei problemi per garantire che gli alimentatori Delta funzionino in modo stabile e affidabile.