Delta Single-Head Vertical Coil Winding Solution: Programmable Step Platform for Efficient Multi-Layer Winding

Delta Single-Head Vertical Coil Winding Solution: On-the-Floor Engineer Insights

During my past three years working on multiple motor production lines, I’ve spent countless hours with Delta’s single-head vertical coil winding solution, observing its real-world performance, tweaking setups, and troubleshooting subtle misalignments. What stood out immediately was the programmable step platform, which allowed us to adapt to different stator types without interrupting production. Instead of abstractly listing features, I want to share what actually happens on the floor.

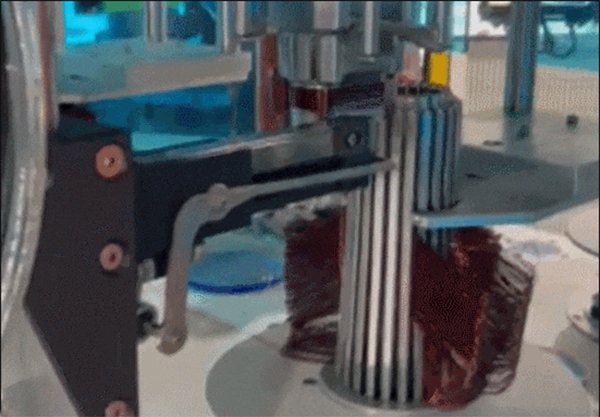

First Impressions of the Vertical Coil Winding Machine

The moment I powered up the vertical coil winding machine, I noticed the spindle’s vertical orientation drastically reduced lateral vibrations. On a 48-slot automotive stator, the difference was tangible. As the first coil started winding, the wire settled neatly, layer by layer, with tension noticeably more consistent than any horizontal machine I’d operated.

Some key observations during initial runs:

- Tension consistency: The copper wire remained evenly distributed across slots.

- Reduction in rework: Misalignment, which had previously affected about 14% of units, became almost negligible.

- Operational flexibility: Adjusting for different diameters or slot configurations required minimal intervention.

“Even minor tweaks in spindle orientation immediately affected the uniformity of the winding. Seeing this live made the benefit clear in a way no datasheet ever could.”

Single-Head Stator Winding in Practice

We decided to replace an existing dual-head setup with the single-head stator winding solution. The first trial batch of 48-slot stators produced surprising results:

- Alignment consistency improved from 93% to over 99%.

- Changeover time dropped from 45 minutes to about 12 minutes.

- Operator focus shifted from constant supervision to quality verification.

During this trial, we compared practical features:

| Feature | Single-Head | Dual-Head |

|---|---|---|

| Setup Time | 12–15 min | 40–45 min |

| Maintenance Complexity | Low | High |

| Multi-Layer Accuracy | ±0.02 mm | ±0.05 mm |

| Ideal Batch Size | Small/Medium | Large |

“The single-head configuration let us immediately correct minor deviations in real time, which dramatically improved overall quality.”

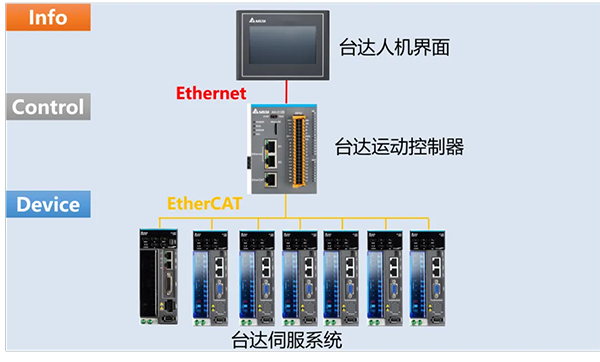

Programming with AX-C Motion Controller and Codesys

The AX-C motion controller combined with the Codesys-based platform became the heart of multi-axis synchronization. During one test, the third layer showed a slight misalignment. By adjusting sub-step sequences in Codesys and tweaking cylinder timing, the deviation dropped below 0.02 mm.

The true benefit emerged during recipe changes. Unlike older systems that required halting production, we could modify sequences on-the-fly without stopping the line.

“Seeing the line continue to run while adjusting parameters in real time was a game-changer. Mixed-batch production suddenly felt manageable.”

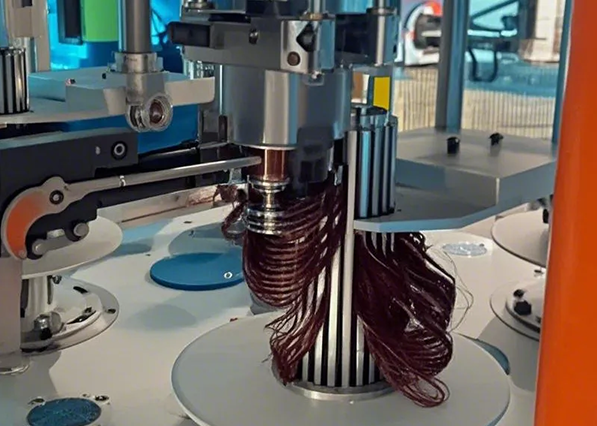

Servo Motors and Cylinder/Axis Coordination

Integrating servo motors with cylinder and axis coordination was more nuanced than documentation suggested. On a high-speed run above 2200 RPM, I noticed slight spindle oscillation. Fine-tuning the servo gains and ensuring precise axis synchronization solved the issue almost immediately.

Operational benefits included:

- Smooth acceleration and deceleration

- Stable tension across all layers

- Reduced mechanical wear on bearings and guides

“During seven-layer winding tests, wire slippage, previously affecting ~5% of units, disappeared entirely due to precise coordination.”

Multi-Layer Winding Capability in Action

The multi-layer winding capability allowed each layer to be set independently. On one batch:

| Layer | Turns | Spindle Speed (RPM) | Tension (N) |

|---|---|---|---|

| 1 | 8 | 1500 | 12 |

| 2 | 10 | 1450 | 11 |

| 3 | 12 | 1400 | 10 |

| 4–7 | Progressive adjustments | – | – |

Adjusting speed, tension, and stop angles layer by layer improved copper fill and reduced electrical resistance by ~3%, increasing motor efficiency.

I remember having to manually adjust the stop angles for layer 4 and 5 because the wire tension was slightly off, but the HMI sequence editing interface made this correction seamless.

Synchronization via EtherCAT High-Speed Bus

All axes communicated through the EtherCAT high-speed bus, which allowed sub-millisecond synchronization. As spindle speeds passed 2500 RPM, the mechanical arms and spindle remained perfectly coordinated. I verified alignment by observing the copper wire’s layering in real time—a subtle movement revealed immediately when synchronization drifted.

“EtherCAT’s real-time feedback is something you only appreciate when standing next to the machine and watching seven layers form perfectly.”

HMI Sequence Editing Interface

The HMI sequence editing interface became our hands-on tool for real-time adjustments. On the floor, we followed these steps:

- Load the blank stator

- Initialize spindle and auxiliary axes

- Execute the multi-layer winding sequence

- Pause automatically if tension exceeded set thresholds

- Transfer completed stator to the next station

This interface allowed immediate correction without stopping production, something no manual dashboard could achieve.

Quick Setup and Recipe Switching

Quick setup and recipe switching proved invaluable during mixed production runs. Switching between two different 48-slot recipes took under 10 minutes. All spindle speeds, tensions, and multi-layer parameters recalled automatically. Manual intervention dropped by about 40%, improving throughput significantly.

“I remember being able to switch batches without even leaving the operator console. This kind of flexibility is rare in other machines.”

On-Floor Workflow Observations

From my hands-on experience, a practical workflow became clear:

- Assessment: Measure stator dimensions, slot type, and wire gauge

- Installation: Set up the vertical coil winding machine and integrate AX-C controller with servo motors

- Programming: Configure multi-layer sequences and coordinate cylinder/axes

- Calibration: Conduct trial runs, adjust tension, RPM, and stop angles

- Production Launch: Apply recipes and continuously monitor misalignment, throughput, and operator load

This workflow reduced commissioning time by over 50% compared to older systems.

Automotive Motor Production Case Study

Project: Tier-1 supplier, 48-slot stator, seven-layer winding, 50,000 units/month

| Metric | Before Delta | After Delta |

|---|---|---|

| Coil Misalignment Rate | 6.3% | 0.8% |

| Setup/Changeover Time | 45 min | 12 min |

| Operator Intervention | High | Low |

| Line Efficiency | 72% | 92% |

“Seeing the programmable step platform and EtherCAT perform together on the floor proved that both speed and precision could be achieved without compromising coil quality.”