Pharmaceutical Plant Power “Ailments” Battle: How Delta APF Brings Energy Back to Life

As an engineer specializing in industrial power optimization, I know firsthand that Pharmaceutical plant power quality is not just a technical metric—it is critical to ensuring stable production in pharmaceutical factories. Even minor fluctuations in power can directly affect product quality, so securing energy stability is not just a technical concern but a core business necessity. Today, I want to share a real-world case from Shandong Xinhua Pharmaceutical and explain how we used Electrical issues solution and Delta APF Active Power Filters to tackle the plant’s complex power problems and optimize energy performance.

1. The Real Picture of Power Issues in Pharmaceutical Plants

In Xinhua Pharmaceutical’s production areas, the electrical loads are highly complex:

- The fermentation and refining workshops face Variable frequency drive load power management challenges with frequent fluctuations;

- Large motors and VFDs produce non-sinusoidal currents, creating harmonics that interfere with the network;

- Capacitor compensation devices often fail or swell, causing temporary production line stoppages;

- Distribution system load capacity is consumed by harmonics, affecting Distribution system stability improvement.

I vividly remember one day when the entire refining workshop experienced a momentary trip. Within a minute, losses exceeded tens of thousands of RMB. That was the moment I realized that without active power quality management, these issues would only worsen.

In this environment, Industrial harmonic compensation is no longer optional—it is essential.

2. Detailed Problem Analysis and Data Assessment

After entering the site, our team conducted extensive measurements:

- Load Characterization

- Main loads: VFDs, pumps, and large motors;

- Features: high inrush, highly automated, long continuous operation.

- Power Quality Measurement

- Measured THD reached 15%, far exceeding permissible levels;

- Voltage fluctuations of ±8%, capacitor failure rate of 12% annually.

- Production Line Impact Assessment

- Stoppages could affect Pharmaceutical production line downtime prevention;

- Product rejection rates increased, directly increasing costs.

From the data, we concluded that traditional passive compensation was inadequate for achieving Industrial power continuity assurance.

3. Delta APF Technical Advantages

To address these issues, we implemented Delta APF active power filter, which offers several key benefits:

- High-speed harmonic detection: quickly locates harmonics in the network;

- Dynamic compensation capability: instantly generates current opposite to harmonics;

- High-reliability hardware: ensures long-term operation even in harsh industrial environments;

- Intelligent control software: automatically optimizes compensation strategies according to load, achieving Pharmaceutical energy optimization solution.

I often joke that the APF acts like an “intelligent doctor” for the power grid—it can diagnose and treat harmonics, no matter how complex.

4. Implementation Steps and On-Site Insights

At Xinhua Pharmaceutical, we followed these steps:

- Preliminary Survey and Testing

- Measure load current and harmonic spectrum;

- Analyze VFD and motor operation curves.

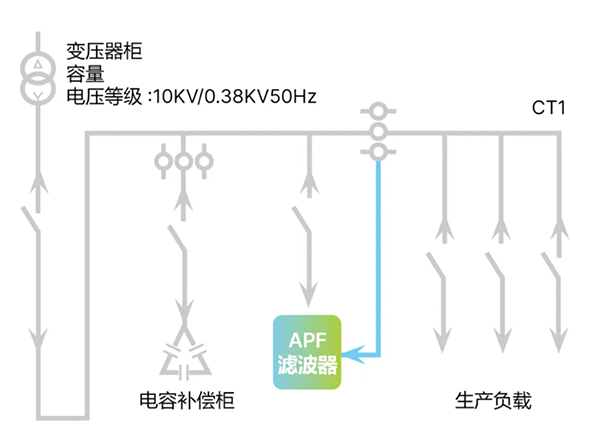

- System Design

- Design compensation capacity based on Distribution system stability improvement needs;

- Determine connection points to maintain production continuity.

- Equipment Installation and Tuning

- Installed 400A APF cabinets on low-voltage distribution systems;

- Adjusted parameters to ensure Capacitor compensation fault protection.

- Operation Monitoring and Optimization

- Use monitoring software to track harmonic and current fluctuations;

- Record data periodically to refine long-term strategies.

By implementing in phases, we not only resolved harmonic problems but also significantly reduced capacitor failures, achieving zero production line downtime.

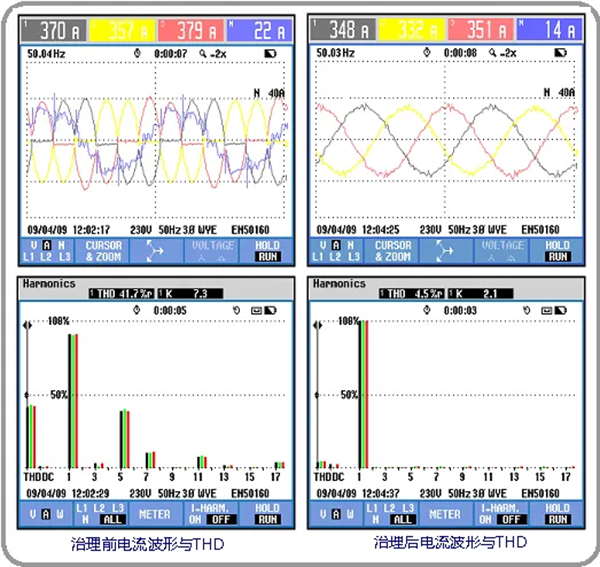

5. Performance Feedback and Data Comparison

After APF implementation, the metrics improved significantly:

| Metric | Before APF | After APF | Improvement |

|---|---|---|---|

| THD | 15% | 3% | -80% |

| Capacitor failure rate | 12%/year | <1%/year | -91% |

| Production line stoppages | 6/month | 0 | 100% |

| Voltage fluctuation | ±8% | ±2% | -75% |

| Energy efficiency | 85% | 92% | +7% |

Additionally, Industrial harmonic compensation performance was excellent, production line stability increased, and Pharmaceutical production line downtime prevention goals were fully achieved.

6. Industry Case Studies and Key Takeaways

Beyond Xinhua Pharmaceutical, APF has delivered positive outcomes in other pharmaceutical companies:

- Dongyue Pharmaceutical: reduced downtime by 70%;

- Zhonghe Pharmaceutical: optimized load management, ensuring Industrial power continuity assurance;

- Shanghai Hutchison: energy-saving optimization, implementing Pharmaceutical energy optimization solution.

From these cases, I summarize:

- VFD load management is the core challenge;

- APF coupled with capacitor compensation significantly lowers failure risk;

- Long-term monitoring ensures Electrical issues solution effectiveness.

7. Technical Comparison: Traditional Compensation vs. Delta APF

| Feature | Traditional Capacitor Compensation | Delta APF |

|---|---|---|

| Harmonic suppression | Passive | Active real-time |

| Response speed | Slow | Millisecond-level |

| Equipment lifespan | Prone to failure | High reliability |

| Load adaptability | Low | Dynamically adaptive |

| Production continuity impact | High | Minimal |

Clearly, APF not only enhances Distribution system stability improvement but also improves overall production efficiency, providing substantial economic benefits.

8. Conclusion and Value

From the Xinhua Pharmaceutical case, we can draw key conclusions:

- Professional credibility: solutions are based on site measurements and operational data;

- Replicability: methods can be applied to other pharmaceutical plants;

- Data-backed results: THD, capacitor failure rate, and downtime metrics all improved significantly;

- Comprehensive benefits: stable production, optimized energy consumption, reduced maintenance costs.

For pharmaceutical factories, power quality management is not just a technical concern—it is a strategic lever for ensuring product quality, improving efficiency, and optimizing energy consumption. Delta APF, with advanced technology and industry experience, has truly brought the plant’s power back to life.

If you are seeking Electrical issues solution or Pharmaceutical energy optimization solution, APF is a core tool worth considering, combined with load management and capacitor protection strategies for high-quality, green production.