Delta AH Series Expansion Modules – Programmable Controller AH Series

PARAMÈTRES DU PRODUIT

- Comprehensive digital and analog I/O module options

- Temperature measurement modules for accurate monitoring

- Network and remote I/O communication modules

- Motion control modules to support advanced automation

Description

CARACTÉRISTIQUES DU PRODUIT

Provides digital modules including input, output, and mixed types.

Offers analog modules for both input, output, and mixed configurations.

Supports temperature measurement modules for precise monitoring.

Includes network modules, remote I/O communication modules, and motion control modules to extend automation capabilities.

CHAMPS D'APPLICATION

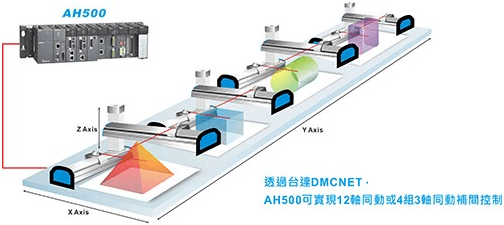

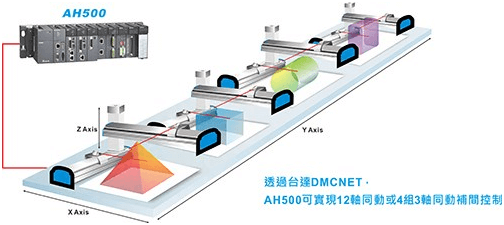

Industrial machinery uses the excellent motion control function of AH500 to realize any three-axis linear interpolation, any two-axis arc interpolation, and any three-axis spiral interpolation and continuous interpolation functions. Through Delta’s DMCNET high-speed communication network architecture, it can achieve 12-axis simultaneous motion or 4 groups of 3-axis simultaneous motion tweening functions within a 1ms command cycle. Whether it is complex process control or precise motion control requirements, it can be realized through AH500, which is effectively used in various industrial machines, such as building materials machines, warp knitting machines, food packaging machines, etc.

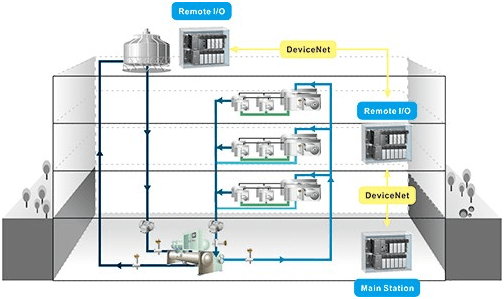

AH500 is a modular controller designed for various high-end automation system applications. Its diverse module selection and excellent system architecture scalability provide excellent solutions for various system application industries; such as remote controllers for building air conditioning (HVAC) and papermaking industry. For I/O needs, the AH500 master station can be used as a central control system to disperse the remote I/O of the AH500 at different floor locations in the HVAC system or at different process stages in the papermaking industry, providing a complete solution for building automation or factory automation.

The system applies the excellent motion control function of AH500 to realize any three-axis linear interpolation, any two-axis arc interpolation, and any three-axis spiral interpolation and continuous interpolation functions. Through Delta’s DMCNET high-speed communication network architecture, it can achieve 12-axis simultaneous motion or 4 groups of 3-axis simultaneous motion tweening functions within a 1ms command cycle. Whether it is complex process control or precise motion control requirements, it can be realized through AH500, which is effectively used in various industrial machines, such as building materials machines, warp knitting machines, food packaging machines, etc.

AH500 is a modular controller designed for various high-end automation system applications. Its diverse module selection and excellent system architecture scalability provide excellent solutions for various system application industries; such as remote controllers for building air conditioning (HVAC) and papermaking industry. For I/O needs, the AH500 master station can be used as a central control system to disperse the remote I/O of the AH500 at different floor locations in the HVAC system or at different process stages in the papermaking industry, providing a complete solution for building automation or factory automation.

SPÉCIFICATIONS TECHNIQUES

FAQ

En tant qu'entreprise intégrée de commerce et de fabrication, nous offrons une gamme complète d'alimentations Delta, y compris des alimentations à découpage, des modules d'alimentation industriels et des alimentations régulées CC, adaptées à l'automatisation industrielle et à divers équipements électroniques.

Oui. Nous fournissons des solutions personnalisées basées sur les exigences du client, y compris la tension, la puissance et les extensions fonctionnelles, avec une assistance technique professionnelle pour garantir la faisabilité.

Nous expédions nos produits par l'intermédiaire de services logistiques et de messagerie fiables, offrant un suivi complet pour garantir que les produits parviennent aux clients en toute sécurité et dans les délais impartis.

Le processus est simple : sélectionner le modèle → soumettre les exigences → confirmer la solution → organiser le paiement → livraison et conseils techniques. Nous fournissons une assistance complète pour garantir le bon déroulement de chaque étape.

Nous offrons la garantie du fabricant d'origine, la fourniture de pièces de rechange, des conseils d'utilisation, des services de maintenance et de dépannage afin de garantir un fonctionnement stable et fiable des blocs d'alimentation Delta.